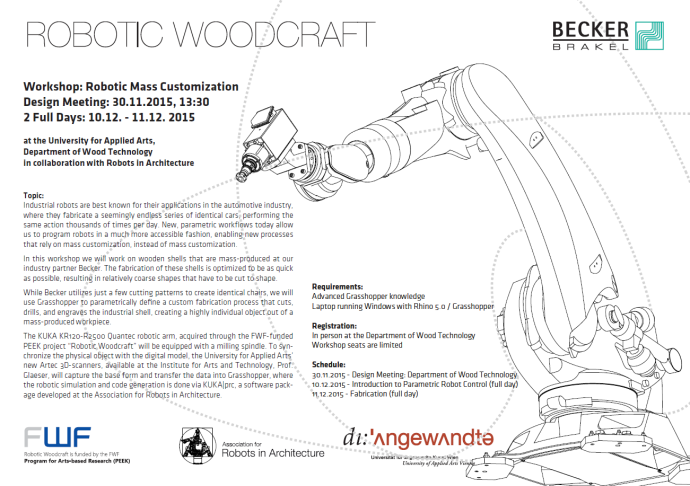

In collaboration with our industry partner Becker we are hosting a workshop on Robotic Mass Customization at the University for Applied Arts Vienna.

Industrial robots are best known for their applications in the automotive industry, where they fabricate a seemingly endless series of identical cars, performing the same action thousands of times per day. New, parametric workflows today allow us to program robots in a much more accessible fashion, enabling new processes that rely on mass customization, instead of mass customization.

In this workshop we will work on wooden shells that are mass-produced at our industry partner Becker. The fabrication of these shells is optimized to be as quick as possible, resulting in relatively coarse shapes that have to be cut to shape.

While Becker utilizes just a few cutting patterns to create identical chairs, we will use Grasshopper to parametrically define a custom fabrication process that cuts, drills, and engraves the industrial shell, creating a highly individual object out of a mass-produced workpiece.

The KUKA KR120-R2500 Quantec robotic arm, acquired through the FWF-funded PEEK project “Robotic Woodcraft” will be equipped with a milling spindle. To synchronize the physical object with the digital model, the University for Applied Arts’ new Artec 3D-scanners, available at the Institute for Arts and Technology, Prof. Glaeser, will capture the base form and transfer the data into Grasshopper, where the robotic simulation and code generation is done via KUKA|prc, a software package developed at the Association for Robots in Architecture.

The workshop will be attended by students, researchers, and industry.